Valorization of Cotton Waste: Agricultural and Biotechnological Perspectives for Sustainable Development

Samar Gogari and Radha

AgriBio Innovations 2025, 2(1): 01-12

INTRODUCTION

A. Background on cotton production Cotton, a globally significant non-food crop, stands as one of the most profitable and widely cultivated agricultural commodities, providing income for over 250 million people worldwide and employing nearly 7% of all labor in developing countries, with its fiber accounting for approximately half of all textile production (Shikha and Bhuyan 2017). The crop’s historical roots trace back to the Indus Valley civilization, and it has since evolved into a cornerstone of both industrial and agricultural economies, especially in countries like India, where it supports the livelihoods of millions of farmers and workers across the value chain (Suresh et al., 2014). Cotton is cultivated in about 75 countries, with India, the United States, and China leading in production, though India’s dominance is occasionally challenged by climate change, soil degradation, and water scarcity, which have recently led to marginal growth and even declines in cultivated area despite reduced fertilizer costs (Suresh et al., 2014; Arora, 2023). This cash crop being sensitive to environmental conditions, requires specific ranges of temperature and rainfall for optimum growth, rendering it vulnerable to climate erraticism and demanding location-specific management practices (Shikha and Bhuyan 2017). The study successfully isolated and identified a cellulolytic strain, S. viridochromogenes LPA75, from cotton agricultural waste compost (CAWC) in Beed, Maharashtra for the improvement of soil fertility and productivity, paving the way for future research into its industrial-scale applications (Chavan et al., 2023). After the advent of Bt cotton, contemporary cotton production has undergone intense yield enhancements, particularly in India where significant yield increment was seen from around 200 kg/ha at the beginning of the century to over 400 kg/ha by the late 2000s (Suresh et al., 2014; Arora, 2023). Despite this progress, challenges like high water and agrochemical use, soil erosion, and environmental pollution still persist in the various stages of cotton cultivation. Hence, to mitigate the ecological footprint of this sector, encouraging and adopting sustainable practices is an important step (Arora, 2023; Zhang et al., 2023). The dependence of the sector on labor-intensive practices, particularly in developing countries, emphasizes its socio-economic relevance while also stressing the need for innovation and policy support to safeguard long-term sustainability and resilience against environmental and market pressures (Najib et al., 2022). Despite its economic importance, largescale cotton production results in substantial agrowaste (particularly cotton stalks and gin residues) which not only hamper agricultural productivity due to slow decomposition and pest infestation but also demand sustainable management approaches (Gogari et al., 2025).

B. Cotton waste issue Cotton waste is a growing and major environmental challenge in the global textile industry, which approximately generates 11.6 million metric tons of cotton waste annually that encompasses both preconsumer and post-consumer sources. This large amount of waste is primarily landfilled or incinerated, contributing to greenhouse gas (GHG) emissions, resource depletion and, soil degradation, while less than 1% of used clothing is recycled into new textiles, highlighting a critical gap in circular economy practices (Johnson et al., 2020). This inappropriate management of cotton waste, like open field burning of residues (cotton stalks), further aggravates the problem of air pollution and poses serious health risks, predominantly in developing countries where waste infrastructure is inadequate (Lu et al., 2023). Cotton cultivation is resource-intensive, requiring large quantities of water, fertilizers and pesticides. The resulting waste which includes contaminated water from textile processing, not only pollutes rivers, lakes and aquifers but also threaten aquatic biodiversity and ecosystem as a whole (Kulkarni et al., 2021). Cotton waste, comprising both gin byproducts as well as field residues, causing millions of tons annually, leads to severe environmental challenges like soil degradation and pest proliferation, from disposal practices of open burning and landfilling. However, its lignocellulosic composition makes it a potential feedstock for renewable biofuels, including ethanol, bio-oil, and fuel pellets, thereby supporting circular economy goals and reducing dependence on fossil fuels (Gogari et al., 2025). Mechanical and chemical recycling technologies have been employed to address this cotton waste. These technologies can transform waste cotton into high-value products like biofuels, yarns and amalgamated reinforcements, thereby reducing the demand for virgin cotton and eventually minimize the environmental footprint (Johnson et al., 2020; Kulkarni et al., 2021; Wang et al., 2023). However, it is still logistically and economically challenging to collect, sort, and process cotton waste, limiting the scalability of recycling initiatives and reducing the dependence on unsustainable disposal approaches (Johnson et al., 2020). Despite these challenges, there are promising pathways to mitigate the cotton waste problem and advance the shift to a circular textile economy through the development of innovative recycling strategies and the advancement of sustainable consumption (Johnson et al., 2020; Kulkarni et al., 2021; Wang et al., 2023).

C. Objective and scope of the review The objective of this review is to investigate the potential of cotton stalk residue, usually discarded by-product of cotton cultivation, as a sustainable and economically viable fiber source for the textile sector. Low-impact raw materials are now essential because of the rising global emphasis on environmental sustainability, circular economy principles, and reduction in industrial waste on a global scale. This review focuses on the chemical composition, methods for fiber extraction, and processing modernizations that make cotton stalks a viable alternative to conventional textile fibers. The scope of this review encompasses recent developments in mechanical, chemical, and biotechnological extraction techniques that improve the usability of cotton stalk fibers. It also evaluates their applications in textile production, like blended yarns, nonwoven fabrics, composites, and industrial materials such as packaging and geotextiles. Furthermore, the review assesses environmental benefits including carbon footprint reduction and waste valorization, along with economic consequences for fiber procurement. Important challenges, including commercial acceptability, fiber quality variability, and technological obstacles, are also discussed. The review concludes by providing recommendations for future research, policy assistance, and industrial integration for strengthening the role of cotton stalk fibers in sustainable textile development.

TYPES AND SOURCES OF COTTON WASTE

A. Field residues Cotton production generates substantial amounts of field residues, largely composed of cotton stalks, bracts, leaves, peduncles and burs which are separated while harvesting and remain on the farms after the fiber is extracted. These residues accounting for a significant amount of the total crop biomass are collectively referred to as cotton plant waste and are regarded as a major by product of cotton cultivation (Gemtos and Tsiricoglou 1999; He et al., 2017). Cotton stalks, which mainly include stems and branches, are the most abundant and widely studied field residue. They are frequently left in the field or incinerated and sometimes removed for other uses like composting, bioenergy or industrial applications (Gemtos and Tsiricoglou 1999; He et al., 2017). Lignocellulosic materials, including cellulose, hemicellulose and lignin make up the majority of the chemical composition of cotton field residues. In comparison to leguminous crop residues the lignin content of cotton stalks is generally high and nitrogen content is lower, which influences their decomposition rates and nutrient cycling in agricultural soils (Rusinamhodzi et al., 2009; He et al., 2017). The light weight and irregular shape of cotton stalks make harvesting and processing challenging, though mechanized collection has been demonstrated as feasible for energy production and other valorization pathways (Gemtos and Tsiricoglou 1999). Field residues also include leaves and other vegetative parts, which, when incorporated into soil, contribute to organic matter accumulation and improve soil fertility over time, though their slow decomposition due to high carbon-to-nitrogen ratios and lignin content can temporarily immobilize nitrogen and reduce nutrient availability for subsequent crops (Rusinamhodzi et al., 2009; Ma et al., 2021). The management of cotton field residues is therefore critical for both agricultural sustainability and resource optimization, with options ranging from soil incorporation to bioenergy production and industrial feedstock utilization.

B. Industrial waste Industrial cotton waste, generated at various stages of textile manufacturing, is a significant by-product of the global cotton value chain and arises from processes such as ginning, spinning, carding, combing, and fabric production, with each step contributing distinct waste streams that vary in composition, fiber quality, and recyclability. At the ginning stage, cotton seeds are separated from the lint, and while most seeds are utilized for oil extraction or animal feed, the remaining non-lint fraction like seed hulls, short fibers (linters), and other impurities constitutes a substantial proportion of industrial waste, with about 15% of the non-lint fraction classified as waste that can potentially be repurposed for applications such as ethanol manufacturing, fertilizer, or oil spill clean-up (Johnson et al., 2020). In spinning mills, waste is generated at multiple points: during carding, where machines open, clean, and align fibers, about 4.7% of the material is separated as waste, with card waste containing a mix of short fibers, dust, and foreign matter; in combing, up to 20% of fiber is removed as noil, which consists of short, tangled fibers unsuitable for fine yarn but still valuable for coarser yarns or as raw material for paper and nonwoven products. Additionally, filter waste from humidification plants, comprising cotton fly and fine dust collected during spinning, accounts for over 1% of the total fiber processed, and is often landfilled or incinerated, representing a missed opportunity for valorization (Rahman and Uddin 2022). The textile finishing and fabric production stages further yield waste such as yarn and fabric trimmings, selvages, and offcuts, which can be recycled into lower-grade yarns, nonwovens, or composite materials, supporting both environmental and economic sustainability. The growing recognition of these industrial cotton waste streams as valuable resources is driving research and innovation in recycling technologies, enabling the transformation of waste into high-value products such as regenerated fibers, composite reinforcements, and bio-based materials, thereby reducing the environmental burden of cotton processing and aligning with circular economy principles (Lu et al., 2023). Efficient management and utilization of industrial cotton waste not only mitigate environmental impacts by diverting waste from landfills and reducing GHG emissions but also create new revenue streams and support the development of sustainable textile manufacturing systems. The types and sources of cotton waste, along with their characteristics, composition, and potential applications, are summarized in Table 1.

C. Waste quantification and environmental impacts Cotton waste quantification is a critical step for understanding the scale and sources of textilerelated waste, with recent global estimates indicating that approximately 11.6 million metric tons of waste cotton are generated annually during garment production alone, highlighting the substantial environmental footprint of the textile sector (Johnson et al., 2020). This waste arises from both industrial processes, such as ginning and fabric cutting, and post-consumer disposal, yet less than 1% of all clothing produced is recycled back into new garments, despite more than 80% of cotton waste being technically suitable for mechanical recycling. The environmental impacts of cotton waste are multi-dimensional, with cotton production accounting for about 2.6% of global water use and 11% of global pesticide consumption, leading to significant concerns over water depletion, agrochemical pollution, and soil degradation (Johnson et al., 2020). When improperly managed, cotton waste is either landfilled or incinerated, both of which release greenhouse gases and toxic substances, exacerbating climate change and air pollution (Johnson et al., 2020; Singhal et al., 2024). In contrast, diverting cotton waste from landfills through recycling or reuse can substantially reduce the industry’s water, energy, and chemical requirements, while also minimizing landfill waste and its associated environmental burdens (Johnson et al., 2020; Rizal et al., 2021).

Table 1: Types and sources of cotton waste

| Type of Waste | Source/Stage | Key Components | Characteristics | Challenges | Potential Uses | References |

|---|---|---|---|---|---|---|

| Field residues | Post-harvest (on-field) | Cotton stalks (stems, branches), leaves, burs, bracts, peduncle | High lignocellulosic content (cellulose, hemicellulose, lignin); low N content | Lightweight, irregular shape; difficult to harvest | Bioenergy, composting, soil incorporation, industrial fiber extraction | (Gemtos and Tsiricoglou 1999; He et al., 2017) |

| Cotton leaves and other vegetative parts | Post-harvest | Leaves and vegetative matter | High C:N ratio, lignin-rich | Slow decomposition; temporary N immobilization | Soil fertility improvement, mulching | (Rusinamhodzi et al., 2009; Ma et al., 2021) |

| Ginning waste | Ginning process | Short fibers (linters), seed hulls, impurities | Low-quality fiber with residual oil, dust | Typically underutilized | Ethanol, absorbents, fertilizer, composite filler | (Johnson et al., 2020) |

| Carding waste | Spinning – carding stage | Short fibers, dust, foreign matter | About 4.7% of fiber rejected | Low strength, mixed contaminants | Nonwoven textiles, coarse yarns, insulation | (Rahman and Uddin 2022) |

| Combing waste | Spinning – combing stage | Noil (short tangled fibers) | Up to 20% fiber loss | Unsuitable for fine yarns | Coarse yarns, paper, nonwoven fabrics | (Rahman and Uddin 2022) |

| Filter waste | Spinning – humidification | Cotton fly, fine dust | ~1% of total fiber processed | Often landfilled or incinerated | Reinforcements, insulation, recycled fiber | (Rahman and Uddin 2022) |

| Fabric trimmings and offcuts | Finishing and fabrication | Selvages, yarn/fabric trimmings, offcuts | Mixed length and composition | Variable quality, dye/finish residues | Recycled yarn, composites, lower-grade textiles | (Lu et al., 2023) |

The valorization of cotton waste into high-value products, such as microcrystalline cellulose or composite materials, offers eco-friendly alternatives for sustainable waste management (Lu et al., 2023; Singhal et al., 2024). Furthermore, recent studies have demonstrated that pyrolysis and chemical recycling of cotton waste can yield valuable products like biofuels and functional biomaterials, further mitigating environmental impacts (Rizal et al., 2021; Silva et al., 2024). However, persistent barriers such as limited collection infrastructure, sorting challenges, and low market demand for recycled cotton continue to hinder the full potential of cotton waste valorization (Johnson et al., 2020; Zhou et al., 2023). Addressing these challenges through improved supply chain management, policy interventions, and technological innovation is critical for minimizing the environmental impacts of cotton waste and advancing the transition toward a circular cotton economy (Johnson et al., 2020; Rizal et al., 2021; Lu et al., 2023). By prioritizing accurate quantification and life cycle assessment, stakeholders can better understand the true cost of cotton waste and implement strategies that maximize resource recovery and environmental protection.

AGRICULTURAL APPLICATIONS OF COTTON WASTE

A. Biofertilizer/Compost The agricultural application of cotton waste as biofertilizer or compost is increasingly recognized as a sustainable strategy for enhancing soil health, improving crop productivity, and supporting circular agricultural systems. Cotton crop residues and post-industrial textile waste, when composted or processed with microbial inoculants, transform into nutrient-rich organic amendments that not only provide essential macro- and micronutrients but also improve soil structure, water retention, and microbial diversity (Abbas et al., 2013; Alui et al., 2020; Ratnam et al., 2020). Composted cotton waste, when applied to crops such as sunflower or lettuce, has demonstrated significant improvements in plant growth parameters, including increased plant height, flower number, grain weight, and oil content, while also reducing the need for chemical fertilizers and mitigating soilborne pathogens (Abbas et al., 2013; Alui et al., 2020). Field trials and research studies have shown that cotton waste biofertilizers, often enriched with phosphate-solubilizing bacteria (PSB), nitrogenfixing microorganisms, and other plant growthpromoting microbes, enhance germination rates and crop yields, with notable benefits observed in degraded or nutrient-depleted soils (Gaikwad et al., 2023; Das and Kim 2024; Mashatleh et al., 2024). The incorporation of cotton waste into soil directly contributes to soil organic carbon, nitrogen, phosphorus, and potassium, supporting long-term soil fertility and reducing greenhouse gas emissions associated with waste incineration or landfilling (Alui et al., 2020; Ratnam et al., 2020; Pires, 2023). Furthermore, the use of cotton waste as a carrier for microbial inoculants in biofertilizer formulations ensures prolonged activity and survival of beneficial microorganisms in the rhizosphere, thereby promoting root development and stress resilience in crops (Gaikwad et al., 2023; Das and Kim 2024; Mashatleh et al., 2024). Recent studies have also highlighted that cotton waste composts and biofertilizers do not adversely affect soil health or crop performance, even when applied in large quantities, and may even stimulate microbial activity and carbon sequestration (Groeneveld, 2022; Pires, 2023). Despite these advantages, the quality and effectiveness of cotton waste-based fertilizers depend on composting conditions, microbial inoculum selection, and application rates, necessitating further optimization for large-scale adoption (Gaikwad et al., 2023; Das and Kim 2024). Overall, the valorization of cotton waste as biofertilizer or compost presents a promising pathway for sustainable agriculture, resource conservation, and waste reduction, aligning with global efforts to promote circular bioeconomy and climate-smart farming practices.

B. Mulching and soil health Cotton waste, including crop residues and end-ofuse textile products, is increasingly repurposed for agricultural mulching, offering a sustainable alternative to synthetic plastic films while enhancing soil health and supporting circular agroecosystems. Recent research demonstrates that low-quality cotton fibers can be upcycled into mulch gel films via advanced processing techniques such as cellulose hydrogel regeneration and hot pressing, resulting in materials that maintain structural integrity during soil coverage and undergo complete biodegradation after soil burial, thus closing the carbon cycle and avoiding persistent microplastic pollution (Rumi et al., 2021). Field and greenhouse trials confirm that cotton-based mulch mats, developed from end-of-use apparel, effectively suppress weeds, conserve soil moisture, and improve crop yields compared to conventional synthetic mulches, while also fully biodegrading within a growing season, which is critical for annual crop rotations and reduces labor for mulch removal (Cao et al., 2024a; Cao et al., 2024b). The incorporation of cotton crop residues as mulch or composted material has been shown to significantly enhance soil organic matter, nutrient availability, and microbial activity, particularly when combined with organic amendments or microbial inoculants, thereby improving soil structure, water retention, and overall fertility (Ratnam et al., 2020). Cotton waste mulch not only mitigates the environmental risks associated with synthetic mulch disposal, such as microplastic accumulation and pesticide contamination, but also supports the transition to climate-smart, resource-efficient agriculture by converting waste into valuable soil amendments (Rumi et al., 2021; Cai et al., 2024). The application of cotton waste mulch is especially beneficial in degraded or water-scarce regions, where it reduces irrigation needs and boosts crop resilience, while ongoing research continues to optimize formulation, application methods, and biodegradation performance for broader adoption in diverse agricultural systems (Cai et al., 2024; Cao et al., 2024a). Overall, the use of cotton waste as mulch represents a promising, multi-functional solution for sustainable soil management and agricultural productivity, aligning with global efforts to promote circular economy practices in the agroindustrial sector.

C. Vermicomposting The agricultural application of cotton waste through vermicomposting presents a sustainable and effective method for converting textile and crop residues into nutrient-rich organic fertilizers, while simultaneously addressing waste management challenges and enhancing soil health. Vermicomposting, which involves the joint action of earthworms and microorganisms to stabilize and decompose organic matter, has been demonstrated to process cotton waste efficiently, including both field residues and post-consumer textile materials, resulting in a final product rich in plant-available nutrients, humic acids, and beneficial microorganisms (Ali, 2013; Mahitha et al., 2016; Singh et al., 2022). Research has shown that vermicomposted cotton residues significantly improve soil nutrient content, particularly nitrogen, phosphorus, and potassium, and enhance microbial activity, which collectively contribute to improved plant growth and crop productivity (Ali, 2013; Mahitha et al., 2016). Studies on ryegrass and other crops have indicated that soils amended with vermicompost derived from cotton waste exhibit higher net nitrogen mineralization rates and better disease suppression, with marked reductions in pathogenic bacterial populations compared to untreated or composted controls (Ali, 2013). The process of vermicomposting cotton waste not only recycles critical nutrients back into agricultural systems but also mitigates the environmental risks associated with the burning or landfilling of cotton residues, thereby supporting a circular economy and sustainable soil management (Ali, 2013; Mahitha et al., 2016). Field experiments and longterm trials further confirm that vermicompost from cotton waste can be applied at practical rates (240 tons per hectare) without adverse effects on soil or crop health, while providing a simple and costeffective method for local farmers to manage organic wastes using locally available materials (Ali, 2013; Mahitha et al., 2016). Overall, the use of cotton waste vermicompost in agriculture represents a promising, eco-friendly approach to waste valorization, soil fertility enhancement, and the promotion of resilient, productive agroecosystems. The agricultural potential of cotton waste spans multiple applications, including composting, mulching, vermicomposting, and biochar production. These processes support sustainable soil and crop management practices, as summarized in Table 2.

Table 2: Agricultural applications of cotton waste

| Applications | Cotton Waste Sources | Process/Techniques | Key Benefits | References |

|---|---|---|---|---|

| Biofertilizer / Compost | Field residues, post-industrial cotton waste | Composting with/without microbial inoculants | Enhances soil nutrients (N, P, K), improves plant growth, boosts microbial diversity, reduces need for synthetic fertilizers | (Abbas et al., 2013; Alui et al., 2020; Ratnam et al., 2020; Gaikwad et al., 2023; Das and Kim 2024; Mashatleh et al., 2024) |

| Mulching and soil health | Cotton crop residues, end-of-use textiles | Mulch mats, hydrogel films, direct field application | Suppresses weeds, retains soil moisture, increases organic matter, improves microbial activity, biodegradable | (Rumi et al., 2021; Ratnam et al., 2020; Cai et al., 2024; Cao et al., 2024a; Cao et al., 2024b) |

| Vermicomposting | Cotton residues, low-grade textile waste | Earthworm + microbial degradation | High nutrient release, boosts N mineralization, enhances plant growth, suppresses soil pathogens | (Ali, 2013; Mahitha et al., 2016; Singh et al., 2022) |

| Water retention and carbon sequestration | Cotton husks, stalks, raw residues | Biochar production, compost application | Improves water-holding capacity, enhances aggregate stability, increases SOC, long-term carbon storage | (Ma et al., 2021; Torres et al., 2024; Wu et al., 2024) |

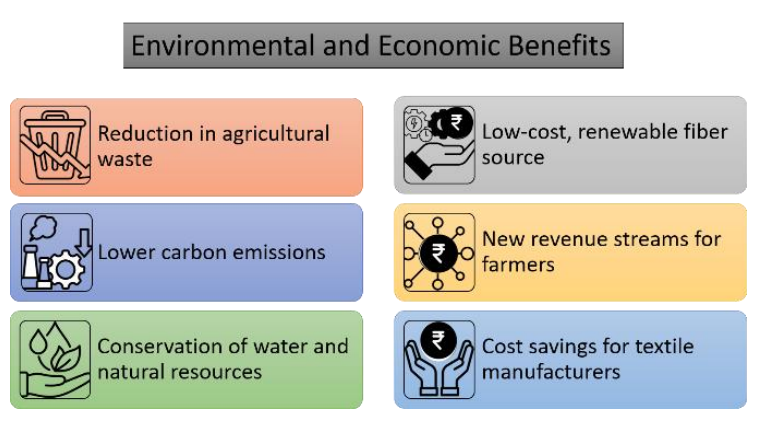

D. Water retention and carbon sequestration Cotton waste, when applied to agricultural soils or processed into value-added products such as biochar, plays a crucial role in enhancing water retention and promoting carbon sequestration, both of which are essential for sustainable land management and climate change mitigation. Recent research demonstrates that biochar derived from cotton husks, produced at pyrolysis temperatures around 400°C, significantly improves the water-holding capacity of sandy soils by increasing microporosity and facilitating the storage of water in micropores, thus reducing irrigation requirements and improving plant available water content (Torres et al., 2024). The incorporation of cotton waste-derived biochar not only enhances soil structure but also provides a stable carbon sink, as the recalcitrant carbon in biochar is resistant to microbial decomposition and remains sequestered in soil for decades, thereby contributing to longterm carbon storage and reduced atmospheric CO₂ concentrations (Torres et al., 2024). Field trials and laboratory studies have shown that cotton waste amendments, including both raw residues and processed biochar, can increase soil organic carbon pools and improve aggregate stability, which further supports water infiltration and retention while reducing surface runoff and erosion (Ma et al., 2021; Torres et al., 2024). The use of cotton waste as mulch or compost also promotes microbial activity, nutrient cycling, and carbon sequestration through the gradual decomposition of organic matter, with long-term incorporation studies in continuous cotton cropping systems revealing significant increases in soil organic nitrogen fractions and enzyme activities associated with nitrogen mineralization (Ma et al., 2021). Overall, the application of cotton waste in agriculture offers a dual benefit: it enhances soil water retention (critical for crop productivity in water-limited environments) and sequesters carbon, thereby contributing to climate change mitigation and the development of resilient agroecosystems (Ma et al., 2021; Torres et al., 2024; Wu et al., 2024). These findings underscore the importance of valorizing cotton waste as a soil amendment for sustainable agriculture, resource conservation, and climatesmart land management. Fig. 1 shows the environmental and economic benefits of cotton stalks valorization.

BIOTECHNOLOGICAL AND INDUSTRIAL VALORIZATION

A. Cellulose and bio-composites Cotton stalks, a significant agricultural residue, are increasingly valorized through biotechnological and industrial processes to extract cellulose and produce biocomposites, supporting circular economy principles. Advanced extraction techniques, such as sulfuric acid hydrolysis, yield nanocellulose with high crystallinity (80.3%) and purity (98.6% α-cellulose), suitable for reinforcing materials (Li et al., 2021). Similarly, steam explosion combined with potassium hydroxide and peroxide treatments produces textile-grade long natural cellulose fibers (27 dtex fineness) with tensile properties comparable to cotton, enabling their use in textiles (Dong et al., 2014). The ligninfirst biorefinery approach via reductive catalytic fractionation achieves 88% delignification, generating phenolic monomers and carbohydraterich pulp that can be carbonized for supercapacitor electrodes (Jindal et al., 2023). Biotechnological routes include microbial conversion of cotton stalk cellulose to lactic acid (51.4 g/L yield by Lactococcus cremoris), which is polymerized into polylactic acid (PLA) for biodegradable plastics (Paswan et al., 2023). Life cycle assessments reveal that bioethanol production from cotton stalks has a lower carbon footprint (0.0113 points) than wood composite (0.0176 points) or biogas routes (0.0108 points), supporting its environmental preference (Ibrahim et al., 2023). These valorization strategies not only mitigate waste but also create high-value products, though challenges in scalability and process optimization remain for industrial adoption.

B. Biochar, bioethanol, biogas Cotton stalks, a major agricultural residue, are increasingly recognized for their potential in biotechnological and industrial valorization through the production of biochar, bioethanol, and biogas, offering sustainable solutions for waste management and renewable energy generation. Biochar production from cotton stalks not only provides a valuable soil amendment that enhances soil health and sequesters carbon but also offers an additional revenue stream for farmers, with studies highlighting its role in reducing air pollution compared to open burning and mitigating pest risks associated with residue accumulation (Kranthi and Kranthi 2023; Phadtare and Kalbande 2024). Life cycle assessment comparisons of different valorization routes reveal that bioethanol production from cotton stalks has a lower carbon footprint and climate change impact than both wood composite and biogas processes, making it an environmentally preferred strategy; the bioethanol pathway involves preprocessing, alkaline pretreatment, enzymatic hydrolysis, and fermentation, efficiently converting the celluloserich stalks into a clean-burning fuel (Ibrahim et al., 2023). Anaerobic digestion of cotton stalks for biogas generation has also demonstrated promising results, with cotton stem waste yielding up to 40.35% total biogas and a notable increase in methane content, though operational challenges such as digester clogging require further optimization (Patel, 2017; Durge et al., 2024). Sequential processing can further enhance resource recovery, as undigested residues from biogas production can be converted into ethanol, maximizing energy extraction from a single feedstock (Patel, 2017). Collectively, these valorization pathways not only address the environmental issues associated with cotton stalk disposal but also contribute to the development of circular and climate-smart agricultural systems.

C. Microbial/enzymatic conversion The biotechnological and industrial valorization of cotton stalks through microbial and enzymatic conversion is a rapidly advancing field that transforms this abundant lignocellulosic residue into high-value bio-based products, particularly bioethanol and lactic acid. Efficient conversion begins with pretreatment, where optimized alkaline conditions like 2% NaOH at 121°C for 60 minutes, effectively remove lignin, exposing cellulose for subsequent enzymatic hydrolysis; studies show that using 100 CMCase units per gram of substrate can yield up to 0.49 grams of reducing sugars per gram of cotton stalk, maximizing fermentable sugar recovery for downstream fermentation (Baig and Dharmadhikari 2012; 2014). Fungal pretreatment, particularly with white rot fungi like Phanerochaete chrysosporium, has also proven effective in selectively degrading lignin and hemicellulose, further enhancing cellulose accessibility for enzymatic action and improving overall sugar yields (Millati et al., 2011). These hydrolysates serve as substrates for microbial fermentation, with recent advances reporting the use of Lactococcus cremoris to synthesize up to 51.4 g/L of optically pure lactic acid from cotton stalk cellulose, a key precursor for biodegradable polylactic acid (PLA) bioplastics (Paswan et al., 2023). Comprehensive reviews highlight that integrating these microbial and enzymatic strategies not only enables the sustainable conversion of cotton stalks into renewable fuels and chemicals but also reduces the environmental burden of agricultural waste, supporting the development of circular bioeconomy models (Keshav et al., 2023).

D. Mycoremediation or bioenzyme production The biotechnological and industrial valorization of cotton stalks for mycoremediation and bioenzyme production is gaining momentum as an eco-friendly approach to agricultural waste management and environmental remediation. Cotton stalks serve as an excellent substrate for fungal growth, particularly for white rot fungi such as Phanerochaete chrysosporium, which are renowned for their ligninolytic enzyme systems capable of breaking down complex lignocellulosic structures and facilitating the degradation of persistent organic pollutants (Shi, 2007; Seoudi, 2013; Akpasi et al., 2023). Mycoremediation studies have demonstrated that the inoculation of cotton stalks with P. chrysosporium accelerates the decomposition process, narrows the C/N ratio, and increases nitrogen content, resulting in mature compost with superior agronomic value and reduced phytotoxicity (Seoudi, 2013). This fungal pretreatment not only enhances the breakdown of lignin and cellulose, making nutrients more accessible for subsequent microbial processes, but also leads to the production of valuable bioenzymes such as cellulases and ligninases, which have broad applications in bioremediation, biofuel production, and the paper industry (Shi, 2007). Recent research also highlights the use of cotton stalks as biosorbents and substrates for enzyme production, offering dual benefits for pollutant removal and resource recovery in sustainable agriculture and industry (Cabarcas et al., 2024; Prakash et al., 2024). These advances underscore the potential of cotton stalks as a renewable resource for mycoremediation and bioenzyme production, aligning with circular economy and environmental sustainability goals.

CHALLENGES AND FUTURE PROSPECTS

Valorization of cotton waste presents significant promise for sustainable material cycles, but its widespread adoption is challenged by technical, policy, economic, and research-related barriers.

1. Technical challenges. Technical challenges are foremost among these. The heterogeneous nature of cotton waste often blended with synthetic fibers like polyester, complicates recycling, as different fiber types require distinct separation and processing methods (Johnson et al., 2020; El Darai et al., 2024; Villar et al., 2024). Mechanical recycling is limited by fiber degradation and contamination, while chemical recycling demands advanced techniques to handle blends and often relies on hazardous solvents, increasing operational complexity and environmental risk (Andini et al., 2024; Abrishami et al., 2024; Pavlopoulou et al., 2024). Current recycling technologies are typically optimized for pure cotton or single-polymer streams, leaving blended or treated materials underutilized (Loo et al., 2023; Moreno-Marrodán et al., 2024). Energy-intensive processes, high input costs for chemicals, and the need for specialized infrastructure further hinder the technical and economic feasibility of large-scale valorization (El Darai et al., 2024; Abrishami et al., 2024). Additionally, the presence of dyes, finishes, and other chemical treatments in waste cotton introduces safety, regulatory, and process efficiency challenges (Meurs et al., 2024).

2. Policy and economic issues. Policy and economic issues also impede progress. The high capital investment required for recycling facilities, coupled with the low market price of virgin fibers, limits the competitiveness of recycled cotton products (Johnson et al., 2020; McCauley and Jestratijevic, 2023). Regulatory compliance, especially regarding chemical use and waste management, increases operational costs and complexity (Mokhtar et al., 2024). Lack of standardized supply chain traceability and insufficient incentives for circular practices further discourage industry stakeholders from adopting valorization technologies (Textile Exchange, 2020). Moreover, the absence of harmonized policies and subsidies for sustainable textile recycling means that most cotton waste is still landfilled or incinerated, contributing to environmental degradation (Johnson et al., 2020).

3. Research and innovation gaps. Research and innovation gaps remain substantial. There is a need for improved methods to efficiently separate and process cotton from blended or multi-material waste streams, as well as for scalable, low-impact chemical and enzymatic recycling technologies (Choudhury et al., 2024; Villar et al., 2024; Yang et al., 2024). Life cycle assessments comparing different valorization routes are limited, making it difficult to identify the most sustainable and economically viable pathways for large-scale adoption. Furthermore, there is insufficient understanding of the global cotton waste supply chain, including the quantity, quality, and distribution of waste at various stages, which impedes decision-making for end-of-life options (Johnson et al., 2020). Research into new valueadded products like advanced composites, biobased chemicals, and functional materials, remains underdeveloped, and more innovation is needed to create markets that do not compete directly with virgin cotton or traditional textiles (Johnson et al., 2020).

CONCLUSIONS

Cotton stalk residue presents a unique opportunity for advancing sustainability in the textile sector by repurposing agricultural waste into valuable fiber resources. This review has highlighted the significant cellulose content and favorable physical properties of cotton stalks, making them a feasible raw material for various textile applications. Advances in fiber extraction, ranging from mechanical decortication to enzymatic retting, have improved the processability and quality of fibers derived from cotton stalks, enabling their integration into nonwoven fabrics, blended textiles, biocomposites, and industrial materials like packaging and geotextiles. The environmental impact of utilizing cotton stalks is substantial. By reducing agricultural waste, decreasing dependency on synthetic or wood-based fibers, and lowering carbon emissions associated with traditional textile production, cotton stalks support key principles of the circular economy. Economically, they offer cost savings for manufacturers and new income avenues for cottonproducing regions. However, achieving commercial viability on a larger scale requires overcoming persistent challenges such as variability in fiber quality, high processing costs, and limited awareness or acceptance among stakeholders. Addressing these obstacles will necessitate a collaborative approach involving technological innovation, policy intervention, and market development. Investments in research and pilot projects, supportive government policies, and targeted communication strategies to educate consumers and manufacturers alike will be essential. If properly harnessed, cotton stalk fibers can become a cornerstone of eco-conscious manufacturing in the textile industry, aligning environmental responsibility with economic opportunity. As the demand for sustainable materials grows, integrating such renewable and locally available resources will play a critical role in shaping the future of global textile production.

REFERENCES

Abbas, T., Nawab, B., Nazli, R., Saleem, R., Lal, A. & Jamil, K. (2013). Efficacy of cotton waste compost and fertinemakil fertilizer on the growth parameter of sunflower plants. Pakistan Journal of Agricultural Research, 26(1), 54-58.

Abrishami, S., Shirali, A., Sharples, N., Kartal, G. E., Macintyre, L., & Doustdar, O. (2024). Textile recycling and recovery: an ecofriendly perspective on textile and garment industries challenges. Textile Research Journal, 94(23-24), 2815-2834.

Akpasi, S. O., Anekwe, I. M. S., Tetteh, E. K., Amune, U. O., Shoyiga, H. O., Mahlangu, T. P. & Kiambi, S. L. (2023). Mycoremediation as a potentially promising technology: current status and prospects—a review. Applied Sciences, 13(8), 4978.

Ali, S. H. N. (2013). Effect of composted and vermicomposted cotton residues on nutrient contents, ryegrass growth and bacterial blight mitigation (Doctoral dissertation, Georg-August-University Göttingen, Germany). Göttingen University Library. http://hdl.handle.net/11858/00-1735-0000- 0015-8FDC-3.

Alui, K. A., Fofana, I. J., Akotto, O. F., & YaoKouame, A. (2020). Effect of a bio-waste based on seed cotton on some properties of soils under market gardening in the Department of Korhogo in the North of Cote d’Ivoire. Scholars Journal of Agriculture and Veterinary Sciences, 7, 65-72.

Andini, E., Bhalode, P., Gantert, E., Sadula, S., & Vlachos, D. G. (2024). Chemical recycling of mixed textile waste. Science Advances, 10(27), eado6827.

Arora, A., United Nations Economic and Social Commission for Asia and the Pacific. (2023). Growth, yield and environmental sustainability of cotton production in India: Performance and policy measures. AsiaPacific Sustainable Development Journal, 30(1), 195-215.

Baig, M. Z. & Dharmadhikari, S. M. (2012). Optimisation of pre-treatment and enzymatic hydrolysis of cotton stalk. Journal of Pure and Applied Microbiology, 6(3), 1437–1441.

Baig, M. Z. & Dharmadhikari, S. M. (2014). Bioethanol production from enzymatically hydrolysed cotton stalk: one approach towards sustainable energy development. Curr. World Environ, 9(3), 940- 946.

Cabarcas, M. T. B., Ramos, R. T., Salas, B. V., Mendoza, D. G., Gómez, A. M., Álvarez, M. A. C. & Sáenz, J. R. C. (2024). Application of cotton stalk as an adsorbent for copper (II) ions in sustainable wastewater treatment. Sustainability, 16(10), 1-20.

Cai, Z., Haque, A. N. M. A., Callahan, D. L., Dhandapani, R. & Naebe, M. (2024). Development of bio-composite mulch film from cotton gin wastes: Study of pesticide residue and outdoor stability and degradation. Science of the Total Environment, 948, 175004.

Cao, H., Ludwig, K., Cobb, K., Scott, C., Jin, Y., Knight, B. & Shen, H. (2024a). Development and evaluation of biodegradable weed control mulch mats from end-of-use cotton waste. Sustainability, 16(16), 7083.

Cao, H., Ludwig, K., Cobb, K., Scott, C., Jin, Y., Knight, B., Burrichter, M. & Shen, H., (2024b). Development and research of sustainable mulch mats from end-of-use cotton textiles. International Textile and Apparel Association Annual Conference Proceedings, 80(1), 1-3.

Chavan, L. N., Shaker, M. D., Deshpande, A. V. and Dixit, P. P. (2023). Screening and Identification of Cellulolytic Streptomyces viridochromogenes Strain LPA75 in Cotton Crop Compost from Beed, Maharashtra. Biological Forum, 15(3), 923-929.

Choudhury, K., Tsianou, M., & Alexandridis, P. (2024). Recycling of blended fabrics for a circular economy of textiles: Separation of cotton, polyester, and elastane fibers. Sustainability, 16(14), 6206.

Das, S. & Kim, P. J. (2024). Biofertilizers from Agrowastes: A path towards sustainable agriculture biofertilizers from agro-wastes: A path towards sustainable agriculture. Asia-Pacific Biofertilizer & Biopesticide Information (APBB), Article 639, p-530. https://doi.org/10.56669/NCBE8246.

Dong, Z., Hou, X., Sun, F., Zhang, L., & Yang, Y. (2014). Textile grade long natural cellulose fibers from bark of cotton stalks using steam explosion as a pretreatment. Cellulose, 21, 3851-3860.

Durge, A., Watkar, P., Chand, B., Kazi, K., Jangitwar, D. & Durge, N. (2024). Biogas generation from cotton waste. International Journal for Research in Applied Science & Engineering Technology (IJRASET), 12(V), 4307–4312.

El Darai, T., Ter-Halle, A., Blanzat, M., Despras, G., Sartor, V., Bordeau, G., & Garrigues, J. C. (2024). Chemical recycling of polyester textile wastes: shifting towards sustainability. Green Chemistry, 26(12), 6857-6885.

Gaikwad, A., Jadhav, K. & Nayak, S. (2023). Conversion of Lignocellulosic Wastes into Biofertilizer using Bacterial Consortium. Current Agriculture Research Journal, 11(1), 125-136.

Gemtos, T. A. & Tsiricoglou, T. (1999). Harvesting of cotton residue for energy production. Biomass and bioenergy, 16(1), 51-59.

Groeneveld, R. (2022). The benefits of returning cotton textile waste to fields. Future Farming.

Gogari, S., Radha, & Sharma, N. (2025). Cotton waste a source of sustainable energy – A review. International Journal of Theoretical & Applied Sciences, 17(1), 01-08.

He, Z., Zhang, H., Tewolde, H. & Shankle, M. (2017). Chemical characterization of cotton plant parts for multiple uses. Agricultural & Environmental Letters, 2(1), 110044.

Ibrahim, R. A., Inan, H. & Fahim, I. S. (2023). A comparative cradle-to-gate life cycle assessment of three cotton stalk waste sustainable applications. Scientific Reports, 13(1), 20781.

Jindal, M., Kumar, A., Rawat, S. & Thallada, B. (2023). Lignin-first biorefinery approach for the valorization of cotton stalks to phenolic monomers. Sustainable Energy & Fuels, 7(16), 3926-3938.

Johnson, S., Echeverria, D., Venditti, R., Jameel, H. & Yao, Y. (2020). Supply chain of waste cotton recycling and reuse: A review. AATCC Journal of Research, 7(1S), 19-31.

Keshav, P. K., Banoth, C., Kethavath, S. N. & Bhukya, B. (2023). Lignocellulosic ethanol production from cotton stalk: An overview on pretreatment, saccharification and fermentation methods for improved bioconversion process. Biomass conversion and biorefinery, 13(6), 4477-4493.

Kranthi, K. & Kranthi, S. (2023). Production of biochar from cotton stalks using the cone-pit open earth kiln technique. The ICAC Recorder, March 2023, 6–22. International Cotton Advisory Committee.

Kulkarni, K., Ayyanagoudar, A., Karande, M. & Ranade, M. (2021). Case study on cotton textile waste management. Journal of Science and Technology, 6(Special issue01), 332–339.

Li, M., He, B., Chen, Y. & Zhao, L. (2021). Physicochemical properties of nanocellulose isolated from cotton stalk waste. ACS omega, 6(39), 25162-25169.

Loo, S. L., Yu, E., & Hu, X. (2023). Tackling critical challenges in textile circularity: A review on strategies for recycling cellulose and polyester from blended fabrics. Journal of Environmental Chemical Engineering, 11(5), 110482.

Lu, L., Fan, W., Meng, X., Xue, L., Ge, S., Wang, C. & Lam, S. S. (2023). Current recycling strategies and high-value utilization of waste cotton. Science of the Total Environment, 856, 158798.

Ma, F., Wang, Y., Yan, P., Wei, F., Duan, Z., Yang, Z. & Liu, J. (2021). Effect of cotton residues incorporation on soil properties, organic nitrogen fractions, and nitrogen-mineralizing enzyme activity under long-term continuous cotton cropping. PeerJ, 9, e11053.

Mahitha, U., Devi, G. D., Sabeena, M. A., Shankar, C. & Kirubakaran, V. (2016). Fast biodegradation of waste cotton fibres from yarn industry using microbes. Procedia Environmental Sciences, 35, 925-929.

Mashatleh, M., Assayed, A., Al-Hmoud, N., Alhaj Ali, H., Al Abaddi, R. & Alrwashdeh, M. (2024). Enhancing sustainable solutions for food security in Jordan: using bacterial biofertilizer to promote plant growth and crop yield. Frontiers in Sustainable Food Systems, 8, 1423224.

McCauley, E., & Jestratijevic, I. (2023). Exploring the business case for textile-to-textile recycling using post-consumer waste in the US: Challenges and opportunities. Sustainability, 15(2), 1473.

Meurs, E., Morshed, M. N., Kahoush, M., & Kadi, N. (2024). Study on Fenton-based discoloration of reactive-dyed waste cotton prior to textile recycling. Scientific Reports, 14(1), 24536.

Millati, R., Syamsiah, S., Niklasson, C., Cahyanto, M. N., Ludquist, K. & Taherzadeh, M. J. (2011). Biological pretreatment of lignocelluloses with white-rot fungi and its applications: a review. BioResources, 6(4), 5224-5259.

Mokhtar, Z., Kenway, S., & Mat Nashir, I. (2024). Challenges for Compliance with Industrial Effluent Regulations— An Industry Perspective. Challenges, 16(1), 1.

Moreno-Marrodán, C., Brandi, F., Barbaro, P., & Liguori, F. (2024). Advances in catalytic chemical recycling of synthetic textiles. Green Chemistry, 26, 11832-11859.

Najib, D. C., Fei, C., Dilanchiev, A. & Romaric, S. (2022). Modeling the impact of cotton production on economic development in Benin: A technological innovation perspective. Frontiers in Environmental Science, 10, 926350.

Paswan, M., Adhikary, S., Salama, H. H., Rusu, A. V., Zuorro, A., Dholakiya, B. Z. & Bhattacharya, S. (2023). Microbial synthesis of lactic acid from cotton stalk for polylactic acid production. Microorganisms, 11(8), 1931.

Patel, V. R. (2017). Cost-effective sequential biogas and bioethanol production from the cotton stem waste. Process Safety and Environmental Protection, 111, 335-345.

Pavlopoulou, K. E., Hrůzová, K., Kahoush, M., Kadi, N., Patel, A., Rova, U., Matsakas, L., & Christakopoulos, P. (2024). Textile Recycling: Efficient Polyester Recovery from Polycotton Blends Using the Heated High-Ethanol Alkaline Aqueous Process. Polymers, 16(21), 3008.

Phadtare, P. & Kalbande, S. (2024). Assessment of agro-residues as biochar feedstock: Cotton stalk, soybean straw, and pigeon pea stalk. International Journal of Research in Agronomy, 7(6S), 36-40.

Pires, S. (2023). Cotton to compost: Transform waste management in the textile industry. Cotton Today. https://cottontoday.cottoninc.com/cotton-tocompost-transform-waste-managementtextile-industry/

Prakash, S., Sharma, K., Dhumal, S., Senapathy, M., Deshmukh, V. P., Kumar, S. & Kumar, M. (2024). Unlocking the potential of cotton stalk as a renewable source of cellulose: A review on advancements and emerging applications. International Journal of Biological Macromolecules, 261, 129456.

Rahman, S. & Uddin, A. J. (2022). Unusable cotton spinning mill waste: A viable source of raw material in paper making. Heliyon, 8(8), e10055.

Ratnam, M., Madhuvani, P., Lakshmipathi, R., Vindya, S. & Rao, G. S. (2020). Recycling of Cotton Crop Residue for Sustainable Cotton Production in Vertisols of Andhra Pradesh, India. Int. J. Curr. Microbiol. App. Sci., 9(8), 1585-1589.

Rizal, S., HPS, A. K., Oyekanmi, A. A., Gideon, O. N., Abdullah, C. K., Yahya, E. B. & Rahman, A. A. (2021). Cotton wastes functionalized biomaterials from micro to nano: a cleaner approach for a sustainable environmental application. Polymers, 13(7), 1006.

Rumi, S. S., Liyanage, S. & Abidi, N. (2021). Conversion of low-quality cotton to bioplastics. Cellulose, 28, 2021-2038.

Rusinamhodzi, L., Murwira, H. K. & Nyamangara, J. (2009). Effect of cotton–cowpea intercropping on C and N mineralisation patterns of residue mixtures and soil. Soil Research, 47(2), 190-197.

Seoudi, O. A. T. (2013). Enhancement of cotton stalks composting with certain microbial inoculations. Journal of Advanced Laboratory Research in Biology, 4(1), 26-35.

Shi, J. (2007). Microbial pretreatment of cotton stalks by Phanerochaete chrysosporium for bioethanol production (Doctoral dissertation, North Carolina State University). North Carolina State University. Retrieved from https://repository.lib.ncsu.edu/items/0bd5dc7 6-a748-4351-9ff5-8e12f0dd7986

Shikha, A. & Bhuyan, S. (2017). Cotton crop: Various aspects and transition from past, present and future. SSRG International Journal of Agriculture & Environmental Science, 4(6), 27-31.

Silva, J. E., Deus Junior, J. O., Calixto, G. Q., Melo, D. M., Melo, M. A., Júnior, V. C. & Braga, R. M. (2024). Colored cotton crop wastes valorization through pyrolysis: a study of energetic characterization and analytical PyGC/MS. Scientific Reports, 14(1), 9359.

Singh, V., Wyatt, J., Zoungrana, A. & Yuan, Q. (2022). Evaluation of vermicompost produced by using post-consumer cotton textile as carbon source. Recycling, 7(1), 10.

Singhal, S., Mittal, A., Anand, S., Mangalam, J., Agarwal, S., Barman, J. & Kumar, R. (2024). Cotton-based fabric waste to microcrystalline cellulose: a sustainable waste management approach. New Journal of Chemistry, 48(38), 16763-16775.

Suresh, A., Ramasundaram, P., Samuel, J. & Wankhade, S. (2014). Cotton cultivation in India since the green revolution: Technology, policy, and performance. Review of Agrarian Studies, 4(2), 26-52.

Textile Exchange (2020). 2025 Sustainable Cotton Challenge: Second annual report (Produced in 2020). Retrieved from https://textileexchange.org/app/uploads/202 1/04/2025_Sustainable-Cotton-ChallengeReport_20201.pdf

Torres, G. N., Amorim, R. S., Raimo, L. A. D. L. D., Faria, O. C., & Couto, E. G. (2024). Water retention in sandy soils of different origins with the addition of biochar. Revista Caatinga, 37, e11792.

Villar, L., Pita, M., González, B., & Sánchez, P. B. (2024). Hydrolytic-assisted fractionation of textile waste containing cotton and polyester. Fibers and Polymers, 25(7), 2763- 2772.

Wang, C., Su, J., Liu, T., Ge, S., Liew, R. K., Zhang, H. & Fan, W. (2023). A sustainable strategy to transform cotton waste into renewable cellulose fiber self-reinforcing composite paper. Journal of Cleaner Production, 429, 139567.

Wu, F., Guo, S., Huang, W., Han, Y., Wang, Z., Feng, L. & Li, Y. (2024). Soil water movement may regulate soil water consumption and improve cotton yields under different cotton cropping systems. Industrial Crops and Products, 211, 118278.

Yang, K., Wang, M., Wang, X., Shan, J., Zhang, J., Tian, G., & Ma, J. (2024). Polyester/cottonblended textile waste fiber separation and regeneration via a green chemistry approach. ACS Sustainable Chemistry & Engineering, 12(11), 4530-4538.

Zhang, Z., Huang, J., Yao, Y., Peters, G., Macdonald, B., La Rosa, A. D. & Scherer, L. (2023). Environmental impacts of cotton and opportunities for improvement. Nature Reviews Earth & Environment, 4(10), 703- 715.

Zhou, C., Dong, J., Zhang, S., Zhang, Q., Wang, M., Zheng, L. & Jiang, W. (2023). Classification of waste cotton from different countries using the near-infrared technique. Textile Research Journal, 93(1-2), 133-139